Logilook

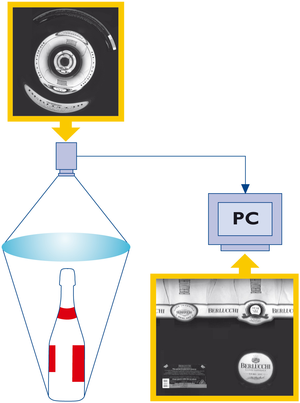

Checks correct labelling by camera.

Regardless of the way the bottle is facing, this checks all its exterior "clothing", through a single high-resolution camera and a special optical unit designed and manufactured exclusively by us. This is the only system able to operate in-line with both cylindrical and shaped bottles.

|

|

MAIN FEATURES::

- Stand-alone system that can be placed on any bottling line immediately downstream of the labelling machine.

- Special optical unit that allows the high-resolution camera to carry out a complete and simultaneous inspection of all the exterior "clothing" of the bottle.

- Special high efficiency, long-lasting, pulsed LED lighting system.

- Patented self-centring infeed guide.

- Works with both cylindrical and shaped bottles.

- It is not necessary to turn or handle the bottles.

- No need to make collages of different images coming from different cameras.

- A new bottle size does not require the bottle profile to be stored in memory.

- Programming of a new size through self-learning of the sample image and selection of areas of interest.

- Possibility to analyse the image for subsequent levels up to the details.

- Possibility to store up to 1000 formats in memory.

- Size changeover by simply calling up the bottle code.

- Display of all the acceptance and rejection parameters.

- Storage in memory and recall of the images of the last bottles that passed through or were rejected.

- Display of all the causes of rejection.

- Statistical information.

- Fully solid-state Logics & Controls dedicated computer; does not need an UPS.

- Possibility to control one-way ejection systems or progressive diverters to eject the containers onto the accumulation table and so guarantee their stability.

DIFFERENT LEVELS OF ANALYSIS:

- Checking label presence and orientation.

- Checking of the position of the labels in relation to each other.

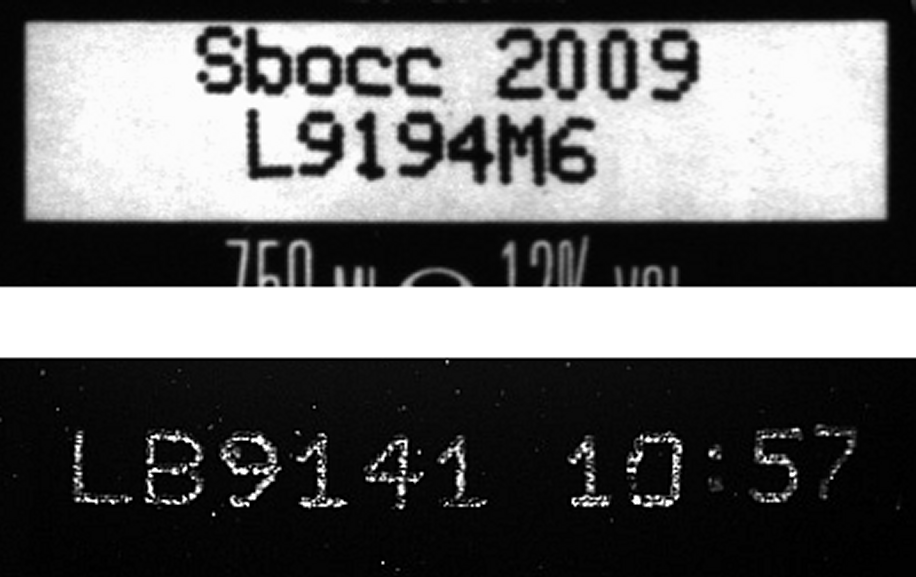

- Checking of the graphic content, inclination and intactness of each label.

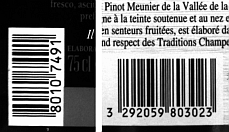

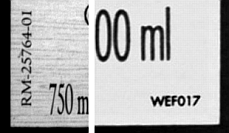

- Checking, at several levels, of particular details such as texts or parts of them, codes, capacities and alcohol content.

- Checking of the neck label and capsule.

- Checking of the position of the labels in relation to a decoration in the glass.

|

||||||||||||

German

German English

English Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Russian

Russian