Loginspect

Checking of quality, intactness and cleanliness of empty containers.

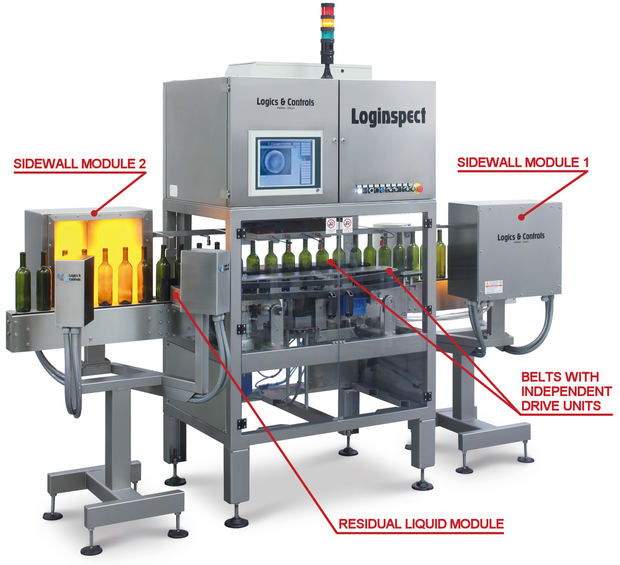

Linear empty bottle inspection system.

Modular inspection system, installed before the filler, to inspect the surfaces of empty bottles and jars made of either glass or PET. It checks that containers are in good condition and clean, free of foreign matter and liquid residues.

SIDEWALL INSPECTION

The sidewalls are inspected to detect foreign matter, contaminants and breakage and to check the degree of scuffing. Two separate modules: the first one at the infeed also checks the profile of the bottle; the other one at the outfeed carries out a more complete check of the walls as the bottle is rotated inside the machine: the independent motorization of the belts allows the bottles to be rotated with a constant angle, irrespective of their diameter.

New multi-camera system: enables the walls to be inspected with unprecedented quality and resolution, without using mirror systems.

RESIDUAL LIQUID MODULE

RESIDUAL LIQUID MODULE

This identifies bottles with residues of water in the bottom, by means of a special high-frequency sensor. It is particularly sensitive to small traces of caustic soda. A special bottle guide enables the maximum sensitivity to be obtained even with diameter variations in the bottles.

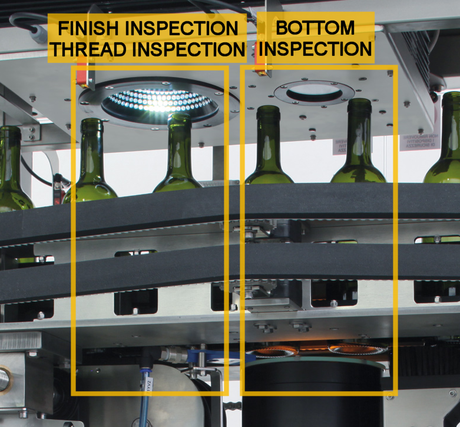

| FINISH INSPECTION | THREAD INSPECTION | ||||

|

The bottle finish is inspected for breakage or scuffing on the sealing surface. A particular angled light enables highlighting of the inner and outer edge of the bottle finish and also the tiniest breakages. |

|

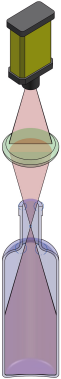

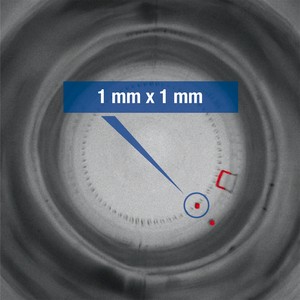

The thread is inspected to identify breakages or scuffing, by means of a special optical unit that enables the entire length of the thread to be displayed as a pale spiral on a black background. The image is expanded and spread on a plane to check it effectively from the processing software. |

|

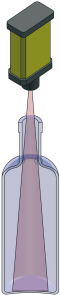

BOTTOM INSPECTION

|

|

|

||||

|

Standard |

Logics & Controls |

TECHNICAL FEATURES:

- Stainless steel frame and panels.

- The main module moves the containers by gripping them at the side by means of 4 special belts with an elastic contact surface. The firm grip of these belts enables the bottom and the lip of the container to be inspected effectively.

- Motorized adjustment of the height of the cameras and the width of the belts, which are the only mechanical adjustments necessary for the size changeover: there is no need to replace mechanical parts.

- Possibility to control one-way ejection systems or progressive diverters to eject the containers onto the accumulation table and guarantee their stability.

- Machine base free of obstructions for easy and quick sanitation.

- All the lighting systems are with high efficiency pulsed LEDs, to guarantee maximum reliability, long life and image repeatability over time.

- High-end industrial PC with touchscreen monitor: no hard disk and no UPS needed.

- Preset for teleassistance via modem or via internet.

EXPANSIONS:

- Possibility to have separate ejectors for the different causes of rejection.

- Possibility to automate the size changeover.

- Possibility to motorize the adjustment of the vertical distance between the conveyor belts.

German

German English

English Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Russian

Russian